CASE 4: Fairbrics

CASE 2: Aloxy

CASE 1: QPINCH

CASE 3: Inopsys

CASE 2: D-CRBN

CASE 1: Ineos

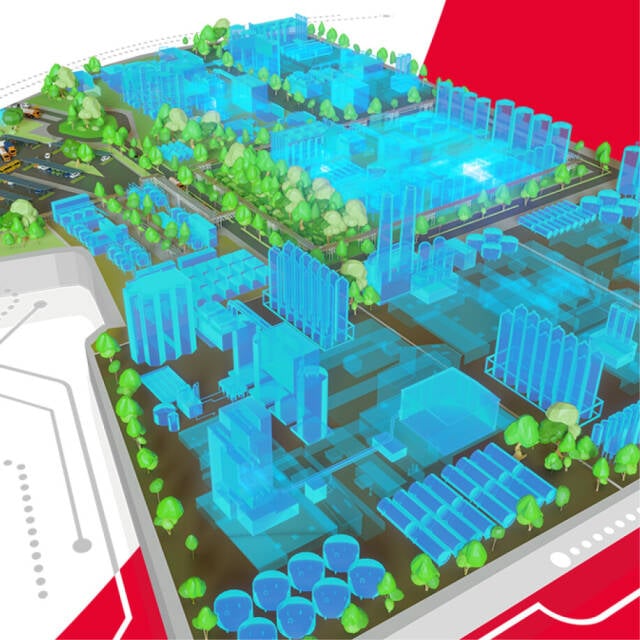

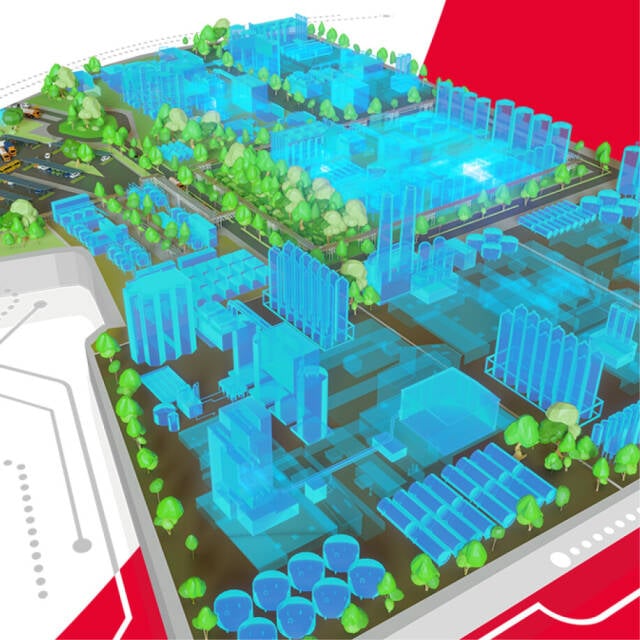

That’s the case as well with NextGen District, an industrial site in the port area. Just like Blue Gate Antwerp NextGen is focusing on circularity. It is a newly developed site and in 2022 the first five companies signed a contract. Three recyclers: BlueChem resident Triple Helix with a polyurethane recycling plant, Bolder Industries which recycles car tyres and the US company PureCycle, a recycler of polypropylene. The other two are Ekopak, an industrial water producer and the US company Plug, green hydrogen production.

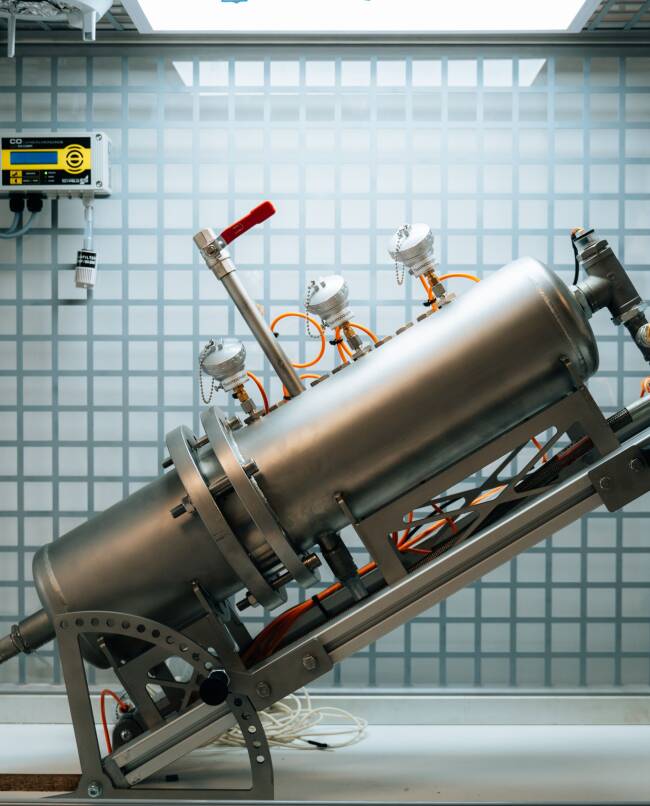

NextGen Demo is an open-air demo zone on NextGen District for pilot installations and ‘proof of concept’ demo-projects. It is the ideal catalyst for sustainable innovations in the field of resource and energy transition. The two companies that will be the first to launch their project are perfectly in line with this ambition (Power to Hydrogen & TripleW).

hub 4 — NextGen District

Electrification & digitalisation: cases

The next step is BlueChem, an incubator for sustainable chemistry. This investment of 10 million euro offers labs & offices. In 2024 the construction of a second BlueChem (XL) lab building will start. The new 2500 m² should be ready at 2025-2026. BlueChem has as its majority-stakeholder essenscia (the federation of chemical & pharmaceutical companies). The city of Antwerp is a co-investor. BlueChem focuses on waste and side streams, process optimization, renewable chemicals and sustainable products. 6 big chemical companies have an office in BlueChem and already 12 startups. The collaboration between both is delivering promising outcomes. BlueChem Kickstart Fund gives subsidies to companies setting up a lab in BlueChem.

hub 2 — BlueChem

BlueApp and BlueChem are both situated on Blue Gate Antwerp, a circular industrial site. Blue Gate Antwerp – a public private partnership - has several establishment conditions like CO2 neutrality which allow only the best circular companies on the site. DHL Express with city distribution activities, the listed logistic warehouse company Montea and Amazon are the first settlers. Needless to say that Blue Gate Antwerp is open for your investments.

hub 3 — Blue Gate Antwerp

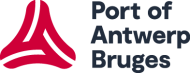

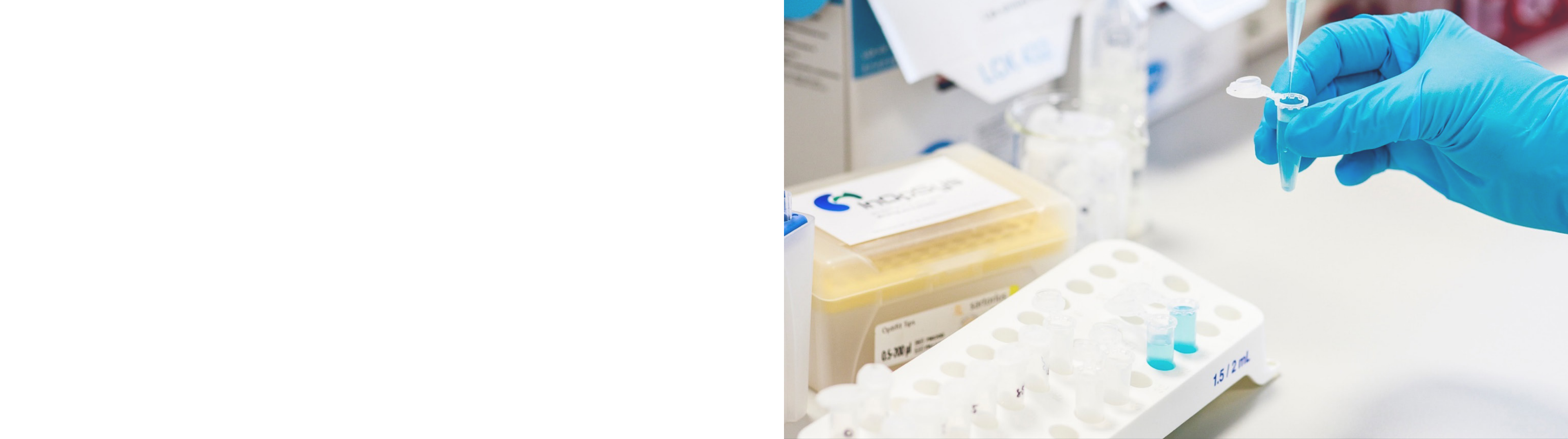

BlueApp is an initiative from the University of Antwerp to bridge the gap between academic research and industrial implementation. BlueApp officially opened in May 2023. The University of Antwerp invested 20 million euro in BlueApp, an open innovation hub for sustainable chemistry & materials, offering labs, offices and a pilot hall. BlueApp focuses on four domains: CO2 as raw material, water treatment & -analysis, process electrification and chemical recycling of plastics. With European and Flemish support, BlueApp will continue to invest in unique research equipment and high-end labs.

hub 1 — BlueApp

Sustainable chemistry: cases

Electrification & digitalisation

The chemical industry has to switch from fossil fuels to (renewable) electricity. Two major uses: generate heat and direct chemical transformation. Secondly the chemical industry has to switch from mechanical & manual operations to more and more digital operations. Antwerp is leading in this field because it hosts production facilities of nearly all major chemical companies. Pre-incubator BlueApp has chosen process electrification as one of its focus areas.

Sustainable chemistry

The city of Antwerp has a full offering to realize this transition. A powerful ecosystem flourishes here, offering a unique and complete innovation journey in sustainable chemistry across all TRLs - from conceptualization in fundamental research in BlueApp, over developing market products in incubator BlueChem, to testing pilot installations on NextGen Demo, and full-scale production facilities on the industrial sites Blue Gate Antwerp and NextGen District. Antwerp’s ecosystem has an innovation hub for every sustainable chemistry entrepreneur, no matter the life stage.

In recognition of Antwerp’s sustained efforts to create innovation hubs, the city received a prestigious award at the worldwide fDi Strategy Awards in 2020.

The chemical cluster is under pressure. Because of the climate change society has to become low carbon oriented. Antwerp is the largest integrated chemical cluster in Europe. In line with the European Green Deal, this industry is working hard on a transition to become more sustainable. That is why established companies, promising startups, knowledge centers and the government are working together to build an ecosystem focused on innovation and entrepreneurship in sustainable chemistry. For the established industry this means CO2 reduction and recycling and closing of the loops. Meanwhile startups are working on new sustainable materials, often biobased, and techniques for CO2 reduction of recycling.

Priority 3:

CASE 3: Fairbrics

CASE 2: Aloxy

CASE 1: QPINCH

CASE 3: Inopsys

CASE 2: D-CRBN

CASE 1: Ineos

Electrification & digitalisation: cases

The chemical industry has to switch from fossil fuels to (renewable) electricity. Two major uses: generate heat and direct chemical transformation. Secondly the chemical industry has to switch from mechanical & manual operations to more and more digital operations. Antwerp is leading in this field because it hosts production facilities of nearly all major chemical companies. Pre-incubator BlueApp has chosen process electrification as one of its focus areas.

Electrification & digitalisation

Sustainable chemistry: cases

That’s the case as well with NextGen District, an industrial site in the port area. Just like Blue Gate Antwerp NextGen is focusing on circularity. It is a newly developed site and in 2022 the first five companies signed a contract. Three recyclers: BlueChem resident Triple Helix with a polyurethane recycling plant, Bolder Industries which recycles car tyres and the US company PureCycle, a recycler of polypropylene. The other two are Ekopak, an industrial water producer and the US company Plug, green hydrogen production.

NextGen Demo is an open-air demo zone on NextGen District for pilot installations and ‘proof of concept’ demo-projects. It is the ideal catalyst for sustainable innovations in the field of resource and energy transition. The two companies that will be the first to launch their project are perfectly in line with this ambition (Power to Hydrogen & TripleW).

hub 4 — NextGen District

BlueApp and BlueChem are both situated on Blue Gate Antwerp, a circular industrial site. Blue Gate Antwerp – a public private partnership - has several establishment conditions like CO2 neutrality which allow only the best circular companies on the site. DHL Express with city distribution activities, the listed logistic warehouse company Montea and Amazon are the first settlers. Needless to say that Blue Gate Antwerp is open for your investments.

hub 3 — Blue Gate Antwerp

The next step is BlueChem, an incubator for sustainable chemistry. This investment of 10 million euro offers labs & offices. In 2024 the construction of a second BlueChem (XL) lab building will start. The new 2500 m² should be ready at 2025-2026. BlueChem has as its majority-stakeholder essenscia (the federation of chemical & pharmaceutical companies). The city of Antwerp is a co-investor. BlueChem focuses on waste and side streams, process optimization, renewable chemicals and sustainable products. 6 big chemical companies have an office in BlueChem and already 12 startups. The collaboration between both is delivering promising outcomes. BlueChem Kickstart Fund gives subsidies to companies setting up a lab in BlueChem.

hub 2 — BlueChem

BlueApp is an initiative from the University of Antwerp to bridge the gap between academic research and industrial implementation. BlueApp officially opened in May 2023. The University of Antwerp invested 20 million euro in BlueApp, an open innovation hub for sustainable chemistry & materials, offering labs, offices and a pilot hall. BlueApp focuses on four domains: CO2 as raw material, water treatment & -analysis, process electrification and chemical recycling of plastics. With European and Flemish support, BlueApp will continue to invest in unique research equipment and high-end labs.

hub 1 — BlueApp

The chemical cluster is under pressure. Because of the climate change society has to become low carbon oriented. Antwerp is the largest integrated chemical cluster in Europe. In line with the European Green Deal, this industry is working hard on a transition to become more sustainable. That is why established companies, promising startups, knowledge centers and the government are working together to build an ecosystem focused on innovation and entrepreneurship in sustainable chemistry. For the established industry this means CO2 reduction and recycling and closing of the loops. Meanwhile startups are working on new sustainable materials, often biobased, and techniques for CO2 reduction of recycling.

Sustainable chemistry

Priority 3: